Giling Basah - The Wet Hulled Coffee Process

The expansive archipelago of Indonesia is the world's fourth-largest coffee-producing region. Coffee cultivation in Indonesia dates back to the 17th century when the Dutch introduced the crop to the islands. It quickly became a significant part of the country's agricultural framework, shaping its economy and culture.

The unique geography and climate of Sumatra, historically Indonesia's main coffee-producing island, gave birth to a distinctive 'wet hulled' process, known as Giling Basah translated from Bahasa as "wet grinding".

This technique, born out of necessity due to Sumatra's humid climate, has provided the defining characteristics of Indonesian coffee, contributing to its unique flavor profile and making it a favorite among coffee connoisseurs globally.

Also, please read our detailed guide on BEST COFFEE BREWING PRODUCTS.

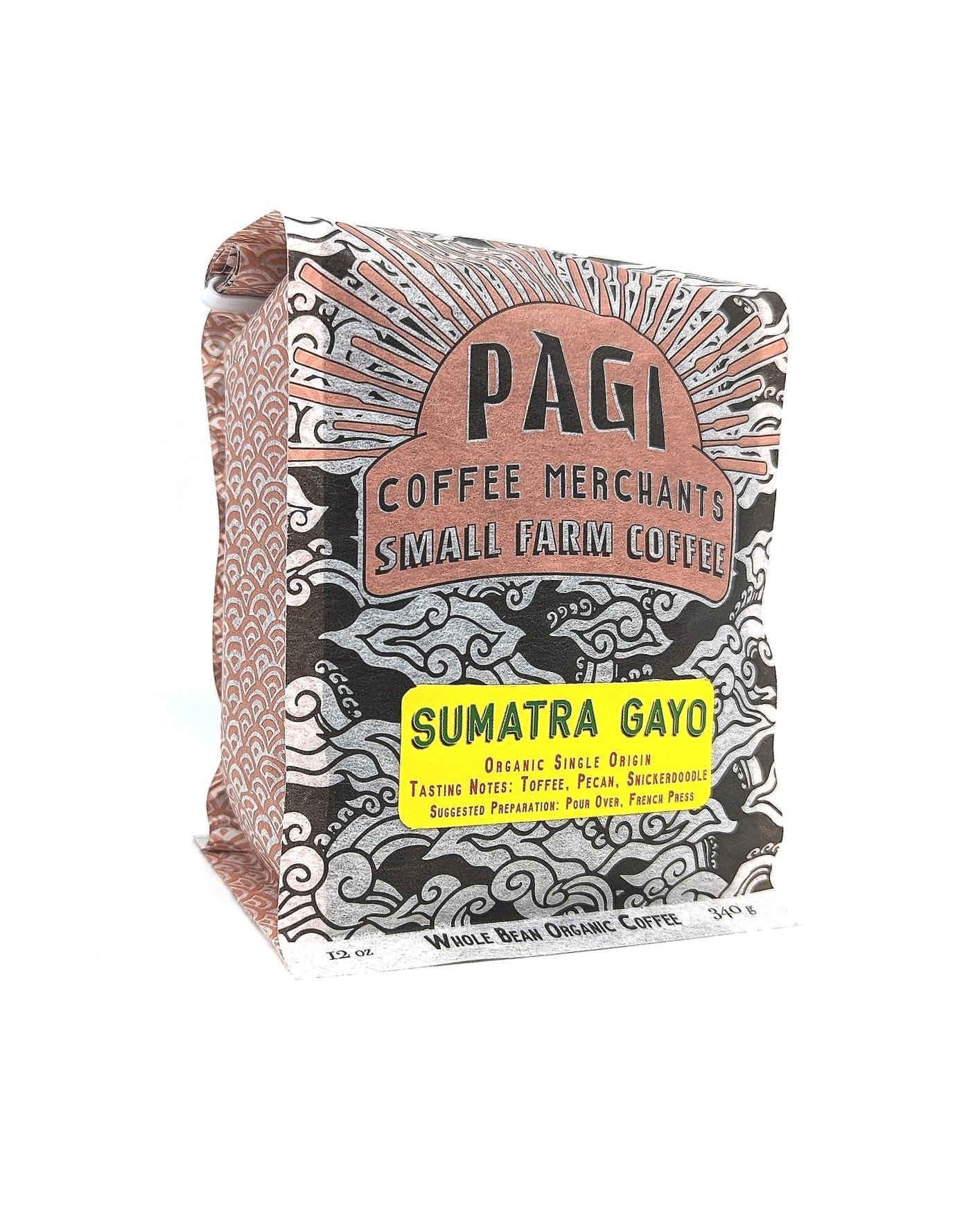

Below are our current Giling Basah Offerings:

The Giling Basah Process: From Harvest to Hulling

A. Harvesting the Coffee Cherries

The journey of Giling Basah coffee begins with the harvesting of the coffee cherries. This process is painstakingly done by hand, which ensures that only the ripest cherries are selected, contributing to the high-quality output. The pickers navigate the coffee plants, carefully plucking the cherries at their optimal ripeness - a task requiring a keen eye and experienced hand. This meticulous approach provides the initial layer of quality control, setting the stage for the unique flavor profile that Sumatran coffee is celebrated for.

Also, check Pagi Coffee’s recommended Best Bluetooth Water Kettles for Coffee Lovers.

B. Traditional Handpicking Methods

Handpicking is done with a 'selective picking' approach, where only the cherries that have reached the perfect shade of dark red are chosen. These ripe cherries are plucked individually, leaving behind the green, unripe ones for later harvests.

This labor-intensive process is repeated several times throughout the season, ensuring that each cherry is harvested at its peak. Experienced pickers can often tell the ripeness by the feel of the cherry in their hands.

This is an age-old technique, passed down through generations, and requires immense patience and skill, and is crucial to the exceptional taste and aromatic richness that sets Indonesian coffee apart.

C. The Importance of Selecting Fully Ripened Cherries

The selection of only fully ripened cherries is an integral step in the production of specialty Indonesian coffee. Ripe coffee cherries are typically a vibrant red color and yield the highest quality coffee. The ripeness of the coffee cherry directly influences the flavor, aroma, and overall quality of the coffee.

The sugars in the fruit reach their peak when the cherry is fully ripe, contributing to a more nuanced flavor in the final cup. Unripe cherries can impart astringency and undesirable flavors to the coffee. Hence, the meticulous selection process, where only the ripest cherries are chosen, ensures that the coffee maintains its acclaimed robust and full-bodied flavor profile.

D. Depulping the Cherries

Once the cherries have been harvested and sorted, the next step in the Giling Basah process is depulping. This involves removing the outer skin or pulp from the coffee cherries to expose the coffee beans inside. In Indonesia, depulping is typically done on the same day as the harvest.

The coffee cherries are placed in a machine known as a 'pulper,' which separates the pulp from the beans through a mechanical process. The pulper is often manually operated and relies on water to help remove the pulp. The depulped beans, still covered in a layer of mucilage, are then collected for the next stage.

E. Fermentation

Following depulping, the beans undergo fermentation. This step involves leaving the depulped beans to rest in water-filled fermentation tanks. During this period, the mucilage layer around the beans is broken down by natural enzymes. The fermentation period varies, but it generally lasts between 24 to 36 hours, depending on the local climate.

This controlled breakdown of the mucilage layer allows slight acidic nuances to develop, which can add to the complexity of flavor in the final cup of coffee. Once fermentation is complete, the beans are thoroughly washed to remove any remaining mucilage before moving on to the next stage of the Giling Basah process.

F. Impact of Fermentation on Flavor Development

Fermentation plays a pivotal role in the evolution of flavor in Giling Basah. The enzymatic breakdown that occurs during this stage is instrumental in the development of the coffee's complex flavor profile. The extended interaction between the beans and the mucilage imparts distinct fruity and wine-like notes, adding to the coffee's depth and uniqueness.

Various factors such as the fermentation duration, the temperature, and the quality of water used can influence the flavor outcome. By carefully controlling these factors, Indonesian coffee producers ensure a flavor experience that resonates with the distinctive character of traditionally processed Indonesian coffee.

The result is a cup of coffee that is rich, full-bodied, and layered with nuances of flavor that continue to unfold with every sip.

G. The Role of Microbial Activity in Flavor Complexity

Microbial activity during fermentation adds another layer of complexity to the unique flavor profile of Indonesian coffee. The fermentation tanks create an environment where specific strains of yeast and bacteria thrive, initiating a process of natural, controlled decay. These microbes feed on the sugars present in the mucilage, producing by-products such as acids, alcohols, and esters.

The interplay of these compounds significantly enhances the flavor complexity of the final product. These micro-transformations, though subtle, work in harmony to create the unmistakable taste of Indo coffee - a medley of earthy, spicy, and slightly sweet notes that harmonize in a full-bodied brew.

Washing and Drying of Parchment-coated Green Beans

H. Washing the Fermented Beans

Following the fermentation process, the coffee beans are now ready to be washed. This step is crucial to remove any residual pulp and mucilage that may still be clinging to the beans. The washing process typically takes place in water channels or washing stations. The beans are thoroughly rinsed with clean, fresh water to ensure all remaining layers of pulp and mucilage are entirely removed.

This cleaning process is meticulous and careful to ensure the purity of the beans. The washed beans, now clean, are referred to as 'wet parchment' due to the pale, parchment-like layer of skin that remains on the beans.

The washing process not only ensures a clean bean is ready for drying, but it also plays a role in flavor development. It halts the fermentation process, which prevents the beans from acquiring overly sour or off flavors.

By carefully controlling the washing process, Sumatran coffee producers strike the delicate balance between allowing the flavors to develop during fermentation and preventing undesirable flavor profiles that could affect the quality of the final cup.

I. Drying the Parchment-coated Beans

After washing, the beans, still coated in their parchment, are spread out to dry in the sun. This method is unlike conventional coffee processing techniques where the parchment is usually removed before the drying stage. The parchment layer acts as a protective shell, safeguarding the green coffee bean inside from potential damage and contamination.

This crucial step not only helps preserve the bean's inherent characteristics but also contributes subtly to the flavor development. The slow drying process under the parchment allows the green beans to absorb the nuanced characteristics of the parchment, subtly influencing the final flavor of the coffee.

J. Influence of Indonesia’s Tropical Climate on the Drying Stage

Indonesia's tropical climate significantly influences the drying stage of coffee beans. The high temperatures and humidity levels typical of this region provide an ideal environment for slow, natural drying.

As the beans dry under the tropical sun, they retain more moisture, leading to a higher final moisture content compared to beans dried in less humid climates. This moisture retention is one of the factors contributing to their unique flavor profile, adding a distinct richness and fullness to the coffee.

The Hulling Process

K. Wet Hulling: The Distinctive Processing Method of Giling Basah

The wet hulling process begins after the coffee cherries have undergone fermentation, washing, and the initial drying stage. The beans still encased within their parchment layer, are only partially sun-dried to a moisture content of about 30-35%. The higher moisture content, compared to other traditional methods, creates a unique environment within the bean, subtly influencing the development of its characteristic flavors.

Following the initial drying stage, the semi-dried beans are hulled in a machine while they're still damp, a step that differs significantly from other processes where hulling is done after fully drying the beans. This wet-hulling process effectively removes the parchment layer, exposing the raw green beans.

The beans, now hull-free, are spread out for the final drying stage. As they dry, the beans turn from a white, almost mushroom-like color, to a dark green-blue hue, a signature characteristic of Sumatran coffee. The beans are allowed to dry slowly to a final moisture content of approximately 13%, the standard for green coffee beans.

The Giling Basah process is specially adapted to Indonesia’s rainy climate and high humidity. It allows for accelerated drying, reducing the risk of fermentation and mold growth, and ensuring the beans' quality despite the environmental challenges.

L. Techniques Used to Remove the Parchment Layer

The removal of the parchment layer from the coffee beans can be accomplished through mechanical or manual means, and both methods have their own benefits and intricacies.

Mechanically, the parchment removal is typically performed using a hulling machine. The beans are fed into the machine while they're still damp from the initial drying stage. The hulling machine uses friction and pressure to crack open the parchment layer, stripping it away from the bean. The friction also rubs off any silver skin remaining on the bean, resulting in a clean, green coffee bean. Mechanical hulling is efficient, allowing for a large volume of beans to be processed quickly, and it is the preferred method during periods of high production.

On the other hand, manual hulling is a much more labor-intensive method. It involves the use of a wooden pestle and mortar to crack open the parchment layer and reveal the green bean inside.

This method is time-consuming and requires skill to avoid damage to the beans. However, manual hulling allows for greater control over the process, and this careful, meticulous method can contribute to the preservation of the beans' inherent characteristics and nuances in flavor.

Irrespective of the method used, the goal remains the same: to remove the parchment layer without causing any harm to the green bean inside, preserving its quality, and enhancing its unique flavor profile.

Impact on Flavor Profile and Characteristics

Body, Acidity, and Flavor Profiles

The full-bodied nature of Sumatran coffee is one of its most distinctive characteristics, and a large part of this attribute can be credited to the Giling Basah, process. The wet hulling method allows the beans to retain a higher moisture content during their initial processing stages.

This additional moisture subtly impacts the development of the coffee bean, resulting in a denser, more substantial body in the brewed coffee. Unlike coffees processed using dryer methods, which often have a lighter, more acidic profile, the wet-hulled Sumatran beans create a brew that is robust and full-bodied.

The coffee's texture is often described as syrupy or velvety, offering a tactile experience that is as much a part of the Sumatran coffee experience as its complex flavors. This full-bodied attribute makes Sumatran coffee an ideal choice for those who prefer a heavier, richer cup of coffee.

Earthy, Herbal, and Spicy: The Flavor Profiles of Sumatran Coffee

One of the most captivating aspects of giving basah coffee is its unique flavor profile, characterized by an earthy and herbal richness, often accompanied by subtle spicy undertones. The earthy notes can be compared to the richness of damp soil or wet leaves, providing a grounded base that sets the stage for the other flavors.

The herbal component often manifests with hints of sage, bell pepper or fresh-cut grass, adding a refreshing complexity to the cup. Often, one can detect a gentle spicy kick, reminiscent of cinnamon or nutmeg, adding an element of surprise to every sip. This amalgamation of flavors, combined with the full body and low acidity, creates a coffee experience that is truly, uniquely Indonesian.

Final Thoughts

While preparing to start our business In 2014, I had the pleasure of visiting and staying at several coffee farms throughout Indonesia. In Jawa Timor, Bali, and Flores, the farmers all told a similar story, expressing their frustration with how difficult breaking into the American market was.

Sumatrans (aka Giling Basahs) had developed a reputation in the third-wave coffee community for being difficult to roast, too funky, and dense. The trend in third wave has leaned toward lighter, acidic coffees. I’m very happy that since then, we have been importing small farm coffee from Indonesia that are processed not just Giling Basah but in many different ways.

However, as a coffee-head, I feel an excellently roasted Giling Basha is hard to beat. You won’t find a more complex and interesting coffee anywhere else in the world.

The process imparts to the coffee its signature low acidity, full body, and complex flavor notes - a cup that is rich, robust, and distinctly Indonesian. Giling Basah coffees can indeed be difficult to roast but I feel we have achieved some excellent results. Our current Blue Moon from Bali is one of our best sellers and a coffee I enjoy more and more with every roast.

The Giling Basah method inherently molds the coffee, endowing it with distinct features that set it apart in the coffee world. Its full-bodied nature, lower acidity, and complex flavors—earthy, herbal, and sometimes spicy—are a direct product of this unique processing method.

It's a tapestry of flavors that unfold with each sip, unveiling layers of depth and richness found in the heart of Indonesia. The method doesn't merely process the coffee; it carves out the quintessence of the bean, underlining its inherent properties.

As you embark on your coffee journey, exploring Indonesian coffee can be a transformative experience. Supporting local farmers who practice traditional methods not only benefits their economy but also contributes to the preservation of this unique coffee processing method. Each cup of Sumatran coffee that you enjoy is a nod to the hard work, dedication, and incredible skill of these producers.

Thanks for reading - Joshua Lee Vineyard (founder)